FUJI Succeeds in World-First 016008 mm (006003″) Component Placement

Pursuing next-generation placement technology in the AI era

Kelsterbach, January 20th, 2026 – FUJI CORPORATION (headquarters: Chiryu, Aichi; Representative Director, President and CEO: Joji Isozumi; hereinafter referred to as “Fuji”) is pleased to announce that it has achieved the world’s first placement of 016008 mm (0.16 x 0.08 mm or 006 x 003 inches) size components on printed circuit boards (PCBs) with its SMT pick and place machine, NXTR, following the successful development of machine technology designed to handle next-generation ultra-small electronic components.

This achievement will be showcased at the 40th NEPCON JAPAN – Electronics R&D and Manufacturing Technology Expo exhibition, January 21, 2026 at Tokyo Big Sight.

There is currently an accelerating shift toward edge AI, where AI processing is performed on the device itself. An era is also emerging in which a wide range of everyday devices, including smartphones, wearable devices, and even medical and healthcare equipment, are autonomously analyze information. Amid these trends toward greater functionality in electronic devices, the number of mounted electronic components is increasing significantly. As a result, further miniaturization and higher-density integration of electronic components have become critical and unavoidable technological challenges.

Even the 0201 mm (0.25 x 0.125 mm, 008004 inches) size component, which has long been considered the smallest standard among currently commercialized electronic components, will eventually reach its limits in the pursuit of higher density to integrate more electronic functions into limited board space. A next-generation component size, 016008 mm (006003″), is being developed in response. 016008 mm (006003″) size components require approximately half of the placement area compared to 0201 mm size components, allowing for higher-density circuit designs.

Four key control technologies enabling the world’s first 016008 mm (006003″) size component placementVier Technologien realisieren die Bestückung von 016008-mm-Bauteilen

FUJI has been providing high-speed, high-accuracy pick and place machines capable of reliably handling very small components. Advancements in the following four key control technologies have made the world’s first placement of 016008 mm (006003″) size components on PCBs possible.

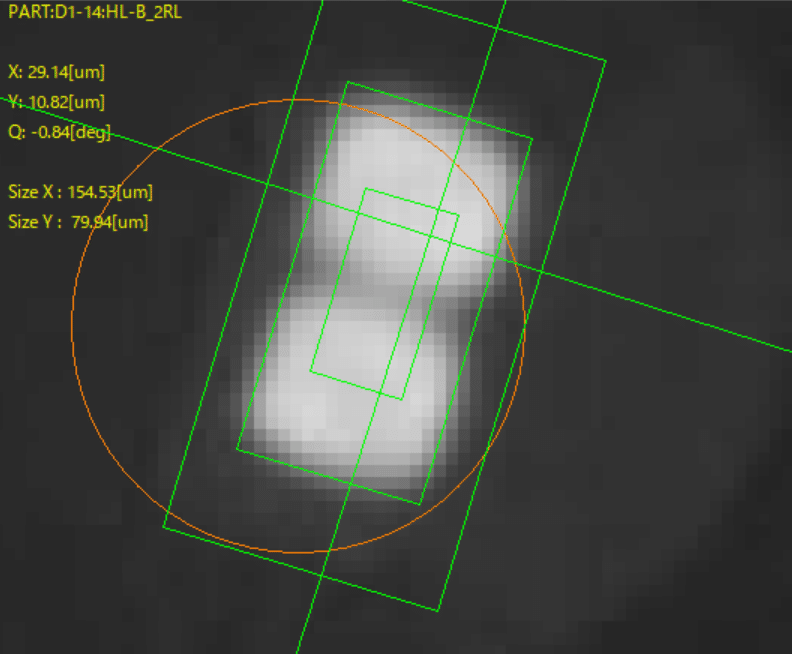

- Stance recognition during handling

The orientation and stance of very small components are checked in real time to ensure optimal part handling. - Highly-accurate part pickup control

Deviations in pickup position and the effects of static electricity are addressed for stable part pickup. - Super-fine control of placement pressure

Pressure is precisely controlled to ensure that very small components are not damaged during placement. - Ultra-high precision placement positioning control

With nano-level position compensation, the highest level of placement accuracy in the industry is achieved.

Aiming to build a comprehensive solution for next-generation very small component placement

To place components 016008 mm (006003″) or smaller, it is essential to optimize not only the placement process but also all processes related to placement, including panel design, solder paste materials, stencils, reflow, and inspection, at a high level.

FUJI is developing machine technology for placement robots while deepening cooperation with partners to build a total process solution, including production materials and related materials, taking the race for the miniaturization of electronic components to a new stage as the edge AI era gets fully underway.