FUJI EUROPE CORPORATION demonstrates “Target ZERO” in SMT manufacturing at productronica

Automated, Data-Driven Placement for Zero Placement Errors, Zero Operators, Zero Downtime, and Zero Limits

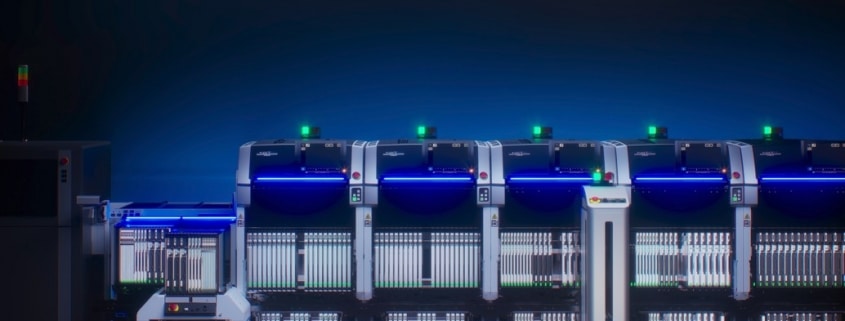

Kelsterbach, September 9th, 2025 – Zero errors, zero operators, zero downtime, zero limits: At productronica 2025, FUJI EUROPE CORPORATION (www.fuji-euro.de) will demonstrate how this vision can become reality in electronics manufacturing. From November 18 to 21 in Munich, the company will present the “FUJI Smart Factory 2.0” at booth 317 in hall A3 – a modular system for automated, data-driven placement processes.

“Just like in Kyūdō, the Japanese art of archery, electronics manufacturing requires precision, clarity, and utmost focus. Every move, every process step has to hit the target – without detours, without waste. Under the motto ‘No waste, just results. Target Zero.’ we will demonstrate at productronica how intelligent and efficient SMT production is becoming reality,” explains Stefan Janssen, Managing Director of FUJI EUROPE CORPORATION GmbH.

FUJI will demonstrate Smart Factory components for both SMT and THT placement. These are linked in a production line with other manufacturers’ machines via Industry 4.0 M2M communication. Within the so-called “FUJI Smart Factory 2.0” (FSF 2.0), all production-related tasks – starting from material preparation through printing and placement – are intelligently connected. The result: production times reduced by 22 percent.

FSF 2.0 is a concept for a highly intelligent, self-optimizing production environment based on networked, autonomous machines. Its goal: production without errors, downtime, or limitations. At its core is seamless data exchange between machines and integration into a flexible manufacturing system that supports individual requirements, such as one-off production or high product variety.

FUJI’s Target ZERO Strategy in Action

FUJI’s Target ZERO strategy is implemented in the NXTR A model. Its objective: zero placement errors, zero machine operators, zero unplanned downtime, and zero placement limits.

A key element here is the Smart Loader. It automatically retrieves the feeders and nozzles needed for upcoming jobs from Smart Storage. Together with AMRs (Autonomous Mobile Robots), these materials are delivered to the production line on time and without manual intervention. This eliminates time-consuming searching and setup work, while ensuring continuous supply to the line. All setups are automatically positioned at the optimal location for maximum productivity – meaning family setups, clustering, or grouping are no longer necessary. The Smart Loader therefore plays a decisive role in achieving “Zero Operators” and “Zero Downtime” by maintaining a seamless material flow.

“Zero Placement Errors” are enabled by tight SPI/AOI integration, automatic error correction, full board ID traceability, and AI-driven analysis of 5M+E data. Potential defects are detected early and automatically corrected. “Zero Operators” are achieved through automated part provisioning (location management, large part supply units), AMR-supported logistics, and visual setup/operation guidance that minimizes manual input. With predictive maintenance, real-time monitoring of all line components, and mobile alerts via FSF Mobile Conductor, “Zero Downtime” becomes attainable.

“Zero Placement Limits” are not just a matter of higher machine performance. They arise from the combination of modular machines, flexible feeding and supply concepts, and data-driven program and process change mechanisms – for example, program changes triggered by a simple scan code. This allows a much broader range of components and panel variations to be processed per line without compromising precision.

Stefan Janssen adds: “Some Target ZERO effects can already be achieved through individual machine functions or modules. For example, at productronica we will present a new all-in-one placement head for our AIMEXR model – flexible for both high-mix and high-volume production. But FUJI Smart Factory 2.0 is the level where all these technical building blocks come together, multiplying their impact across the entire production line. We are driving our Target ZERO strategy forward by combining automation with AI intelligence.”