FUJI EUROPE CORPORATION at SMTconnect: Automation of placement is the future

The automated and autonomous production is gaining momentum

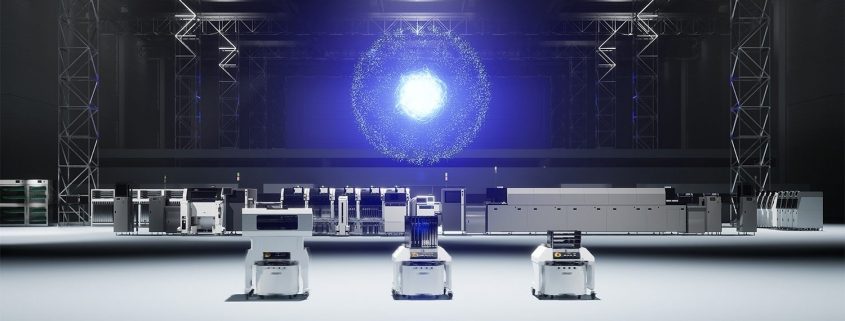

Kelsterbach, April 3rd, 2024 – Companies have never had to adapt to changing market demands and scale production as rapidly as they do now. Automation is the lever to easily align processes with different product types or production quantities. This also applies to placement. FUJI EUROPE CORPORATION GmbH ( www.fuji-euro.de) will showcase components for the FUJI Smart Factory 2.0 at SMTconnect from June 11th to 13th in Nuremberg (Hall 4, Booth 4-321), including various placement machines and newly developed RH placement heads. The goals: zero placement errors, zero machine operators, zero machine stops.

At the exhibition, FUJI presents components of a Smart Factory for SMT and THT placement, which are interconnected in a production line according to the principles of Industry 4.0 via M2M communication with machines from other companies. In the FUJI Smart Factory 2.0, all production-relevant tasks, starting from material preparation and extending beyond printing and placement processes, are intelligently interconnected. The result is a 22 percent reduction in production times.

The R machine series optimizes production preparation and maintenance processes, while automating manual placement processes for comprehensive networking and self-optimized production. In SMT placement, the NXTR-S offers a modular design that allows for quick adjustments to changing production needs. Heads, units, and even entire modules can be replaced without the need for tools. Additionally, the AIMEXR is designed for uninterrupted operation and can accommodate up to 130 different part types, producing panels with dimensions of up to 1,068 x 610 mm.

The sFAB-D, a placement machine designed for automated placement production, streamlines the labor-intensive THT (Through-Hole Technology) placement process, significantly enhancing efficiency while ensuring high precision. This machine offers flexibility to accommodate various part sizes, shapes, and delivery methods, ranging from wired components to larger specialized parts like transformers.

Automation fosters flexibilization

In FUJI’s Smart Factory, automation is aimed at liberating manual tasks and simplifying processes, ultimately speeding them up. This objective also contributes to enhancing the flexibility of SMT manufacturing.

“The complexity, customization, and miniaturization in SMT manufacturing are on the rise.For placement, this means it must be flexible enough to adapt to various components and groups, without compromising precision,” explains Stefan Janssen, Managing Director of FUJI EUROPE CORPORATION GmbH

These challenges are supported by the new RH placement heads that FUJI is presenting at the trade show. Among other features, they offer the ability to adjust the clearance height of the placement heads using a so-called sub-Z-axis. With the help of the contact sensor on the head, it is checked whether the part has touched the circuit board. ‘This precision and adaptability increase flexibility in manufacturing and can be particularly useful when processing various components or assemblies that have different requirements for placement,’ says Stefan Janssen.”

The new RH placement heads that FUJI is unveiling at the trade show are compatible with the R machine series (NXTR-A/-S as well as AIMEXR). By combining a newly developed 2RV module with RH28 heads, W08t feeders, and MFU-63 feeder carts, the NXTR achieves a throughput of 120,000 cph (on a 795 mm module length). This represents a 39 percent improvement compared to the NXT III placement machine.

Stefan Janssen explains: “At SMTconnect, FUJI demonstrates further automation solutions that minimize manual tasks, thereby addressing the growing shortage of skilled labor. At the same time, alongside flexibility, high-speed, and high-precision placement, we are increasingly focusing our machines on energy efficiency in line with the urgent need for an industrial energy transition.”

Visitors can experience the NXTR-S in action firsthand via ‘Robust Processes and Technologies through Automation and Digitalization’ as part of the Future Packaging Line, located at booth 4-311 in Hall 4, hosted by Fraunhofer IZM.”

FUJI

FUJI